Industrial Scale Wiped Film Distillation Unit

Overview of Wiped Film Distillation Technology

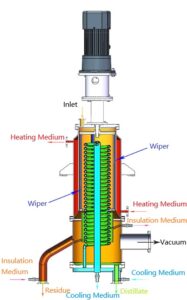

The wiped film distillation separation process is shown in the diagram.

The material is added from the top of the evaporator, and is continuously and uniformly

distributed on the heating surface through the material liquid distributor on the rotor. The

scraper scrapes the product into an extremely thin, turbulent liquid film. The interior of the

evaporator is in a high vacuum state, and the material absorbs heat on the heating surface

and escapes from it. The free path of light molecules is greater than the distance from the

heating surface to the condensing surface. They collide with the condenser and are captured

to form a new liquid flow, which flows down the condenser tube and is discharged through

the bottom lightweight discharge tube; The free path of heavy molecules is smaller than the

distance from the heating surface to the condensation surface, kept within the liquid flow

layer of the heating surface, collected through a circular channel at the lower end of the

heating zone, and then discharged from the heavy material discharge pipe on the side.

A complete wiped film distillation device includes components such as feed

unit, evaporator, external cold trap, discharge unit, heating unit, cooling unit, vacuum unit,

etc. The selection of various components and the reasonable adaptation of the properties,

process requirements, and existing resource conditions of the separated materials are

necessary to ensure that the entire equipment meets the usage requirements.

The multi-stage thin film and wiped film evaporator are connected in series, and through

continuous multi-stage distillation, the separation of multi-component complex mixtures can

be achieved. Multiple experimental demonstrations are required before selection, and simple

assembly is not allowed. The QXscientific team has over ten years of experience in selection

and use, carefully recommending each set of device solutions to customers, and assisting

users in optimizing the use process of each set of devices to the best.

Our characteristics

1. Different evaporator

Visual evaporator, Clean evaporator, Special evaporator, Upper outlet evaporator

Visual evaporator Clean evaporator Special evaporator Upper outlet evaporator

2. Different discharge

3. Different external cold trap

Single liquid nitrogen cold trap, anti clogging cold trap, dual use cold trap, dual cold trap

Single liquid nitrogen cold trap Anti clogging cold trap Dual use cold trap Dual cold trap

4. Design of continuous feeding and discharging material transportation method, key technology obtained national patent certificate.

5. The material pipeline is fully jacketed for insulation, extending the scope of equipment use. For products with high melting points and high viscosity at low temperatures, good performance can also be achieved through heat tracing.

6. The detachable and clean evaporator design is suitable for small batch and multi variety

company applications, greatly avoiding cross contamination caused by product replacement.

This evaporator design has obtained a national patent certificate.

Specification

| Model | QX-20S | QX-50S |

| Feeding rate (L/h) | 40-200 | 100-500 |

| Effective evaporation area (㎡) | 2 | 5 |

| Cooling area of internal condenser (㎡) | 5 | 8 |

| Feeding flask volume (L) | 200 | 200 |

| Vacuum level(mbar) | ≤0.001 | ≤0.001 |

| Operation temperature (℃) | ≤350 | ≤350 |

| Electrical requirement | 220V, 50/60Hz; 380V, 50/60Hz (other options can be provided) | |

| Equipment height (cm) | 500 | 750 |